ICAM

01

With ICAM, Skladišna logistika is entering a new era of efficiency, accuracy and space optimization. Companies that recognize the value of automation and technology have the opportunity to transform their operations, ensuring faster and better delivery of goods, with significant cost savings. ICAM is an international company specializing in automated storage systems that enable space optimization, operational efficiency improvement and cost reduction.

02

ICAM’s smart warehouse systems use advanced technologies to automate the handling of goods, reducing human intervention and minimizing errors. ICAM offers solutions adapted to the specific needs of each company, whether it is a small business or a large distribution center. It provides smart, flexible systems that are designed for the future of storage – where speed, precision and optimization become synonymous with success.

03

The combination of Skladišna logistika and advanced technologies represents a key step towards the future of business. With increasing demands for faster and more accurate delivery, digitization and automation are becoming imperative for companies that want to remain competitive.

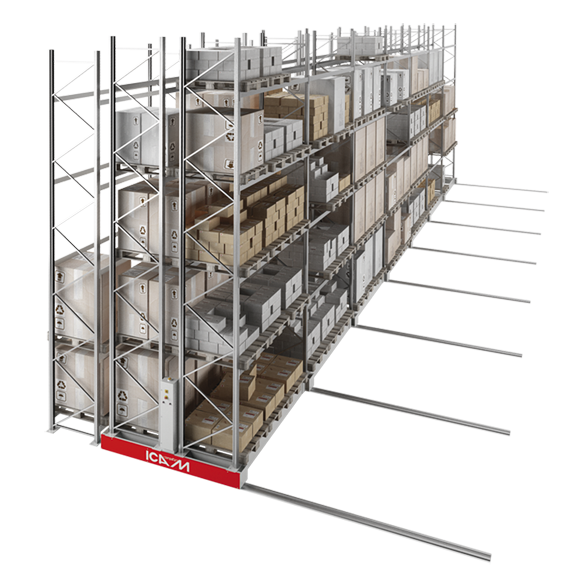

Compatta

Compatt a is a semi-automatic mobile system with racking mounted on mobile bases that use a motorized mechanism to slide along guide rails set into the floor. At the heart of COMPATTA are mobile bases mounted with racking which use a motorized system to run along rails integrated into the floor. It opens and closes up, as required, to provide access just to the aisle in which the material required is stored. This movement can be achieved by the warehouse operator manually pressing a button or using a remote-control device. Compared to traditional static racking COMPATTA can save up to 40% of floor space or alternatively offer up to 80% increased storage capacity in the same footprint. The return on your investment is fast. You will soon have additional space which can be allocated for other use or you can increase your stock holding without the need for any investment in major structural changes.

SILO²

SILO² is the multi-column automatic vertical warehouse for intensive storage, offering maximum adaptability to real warehouse needs. SILO² represents the rapid and economical storage solution for the picking and depositing of medium-small products, even those of very high specific weight, offering capacities adequate for the actual load : moulds, tools, printing cylinders, mechanical and electronic components, small parts, spare parts, tissue rolls, drugs, medical equipment, etc. Its modular design allows you to create warehouses from 2 to 7 columns, sized to meet every space requirement . A single SILO² warehouse can, in fact, replace the work of multiple single-column warehouses, ensuring maximum exploitation of all the available space, not only vertically but also horizontally.

SILO Plus

SILO Plus is the vertical warehouse with translating trays, multi-column, for the storage and fast picking of light loads (max 100 kg). Thanks to the exclusive handling technology and the appropriate sizing of the trays (size and capacity), SILO Plus represents the ideal storage solution for the rapid fulfillment of orders . SILO Plus offers unprecedented operational performance for a multi-column warehouse, ensuring high throughput and a rapid return on investment . The trays, available in a variety of sizes, can be designed to be equipped with standard Euro cassettes and containers . The boxes, which are easily removable and movable, are perfectly suited to any storage need for light items, drastically reducing the time needed to move goods in the warehouse and increasing productivity. The items necessary for picking are immediately available at the work bay where the operator is located, already divided by product type and/or picking logic, speeding up order fulfillment and consolidation activities.